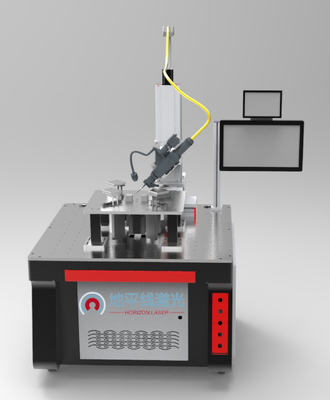

1000-6000W Multi-axis laser welding machine for 3D/4D/5D/6D welding

Multi-axis laser welding machine controls the movement of the welding head through multiple motion axes, realizes multi-track welding of complex products, and is suitable for application scenarios with high welding precision and batch product processing. It is widely used in lithium battery industry, 3C industry, kitchen and bathroom industry.

Features

Servo motor is matched with reducer to realize high-speed and large-torque movement;

Simultaneous multi-axis linkage to achieve a processing track similar to that of a manipulator;

The matching material tray can realize large-scale and batch one-time welding; the open IO handshake interface can be processed with automated production lines.

Technical Parameters

| Laser | CW fiber laser, QCW laser |

| Laser power | 1000-6000W |

| Motion axis | 4- axis ( 3- axis, 5- axis, 6- axis optional), rotation axis |

| Welding head | Conventional welding head, swing welding head (weld seam 0.2 ~ 5 mm ) |

| Welding mode | Continuous welding (sealed welding, stitch welding, tailor welding, fillet welding), spot welding |

| Processing range | Length, width and height: 200-900mm (larger size can be customized) |

| Drive method | Servo motor (linear motor optional) |

| Repeatability | ± 0.03mm |

| Other optional configuration | Double station, CCD positioning, conveyor belt loading and unloading machine, wire feeding mechanism |